The metallic casting business is consistently evolving, pushed with the demand for increased precision, enhanced top quality, and lessened defects. During this landscape, the force casting equipment plays a vital position. However, for one of the most demanding programs, a specialised sort of casting equipment is needed: the vacuum force casting machine. this short article explores the exclusive advantages of these equipment, concentrating on how they greatly enhance the precision and high quality of steel casting, especially for precious metals like gold and platinum.

Table of contents:

The Advantages of employing Vacuum tension Casting Machines for High-high-quality success

How Vacuum force Casting boosts the precision of Gold, Platinum, together with other Metals

Why Vacuum tension Casting is important for substantial-Precision Industries

the benefits of utilizing Vacuum force Casting devices for top-Quality final results

Vacuum stress casting devices offer a substantial leap forward when compared to common casting techniques. The Main reward lies inside the elimination of air pockets and fuel porosity within the casting. By accomplishing the casting method underneath a vacuum, the molten metallic is permitted to flow much more freely and absolutely fill the mold cavity. This results in denser, stronger castings with fewer interior defects. Moreover, the applying of strain over the solidification phase really helps to additional consolidate the metal, reducing shrinkage and strengthening the overall high-quality. This makes vacuum tension casting perfect for manufacturing intricate and complicated styles in which even the smallest imperfections can compromise the functionality or aesthetic appeal of the ultimate solution.

How Vacuum strain Casting boosts check here the precision of Gold, Platinum, as well as other Metals

The superior benefit and unique Homes of important metals like gold and platinum necessitate Remarkable casting precision. Vacuum gold casting device technological know-how is especially intended to satisfy these demanding specifications. The vacuum environment not just prevents oxidation of the molten metal and also makes sure a cleanse and dependable casting system. This is particularly critical for gold, which can easily tarnish or establish surface area defects if subjected to air through casting. What's more, the controlled tension used for the duration of solidification promotes uniform grain composition and minimizes the chance of cracking or distortion. This brings about castings which have been dimensionally correct, possess superb surface end, and retain the specified mechanical properties.

Why Vacuum force Casting is important for large-Precision Industries

significant-precision industries, for example aerospace, medical system manufacturing, and significant-close jewelry output, trust in vacuum pressure casting to attain the stringent top quality expectations necessary for their applications. The ability to deliver castings with limited tolerances, minimum defects, and constant material properties is paramount in these sectors. such as, within the aerospace industry, vacuum pressure cast parts are Employed in crucial engine areas in which reliability and overall performance are non-negotiable. in the same way, in professional medical product production, vacuum strain casting guarantees the biocompatibility and structural integrity of implants. the advantages increase to jewellery earning likewise, wherever intricate designs and flawless finishes are essential for making substantial-benefit parts. eventually, vacuum stress casting supplies the required control and precision to meet the demanding demands of these industries. As evidenced by solutions just like the TAKJ-VC-W available at https://taeantech.com/products/takj-vc-w, these machines are especially intended to cater towards the precision essential by vacuum strain casting procedures.

In conclusion, vacuum strain casting equipment are indispensable applications for accomplishing superior precision and exceptional high quality in metallic casting. The mix of vacuum atmosphere and managed pressure removes widespread casting defects, boosts product Homes, and makes certain dimensional precision. For industries demanding the best levels of performance and trustworthiness, purchasing vacuum tension casting engineering is not simply a option but a requirement. evaluate the distinct necessities of your application and take a look at the various vacuum stress casting methods available to unlock new prospects in metal casting and elevate the quality of your ultimate products and solutions.

Rick Moranis Then & Now!

Rick Moranis Then & Now! Kelly McGillis Then & Now!

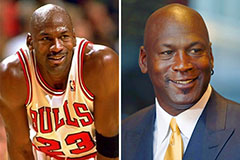

Kelly McGillis Then & Now! Michael Jordan Then & Now!

Michael Jordan Then & Now! Bill Cosby Then & Now!

Bill Cosby Then & Now! Robin McGraw Then & Now!

Robin McGraw Then & Now!